Modular Rubber Flooring

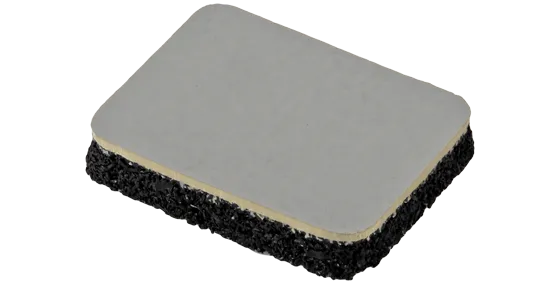

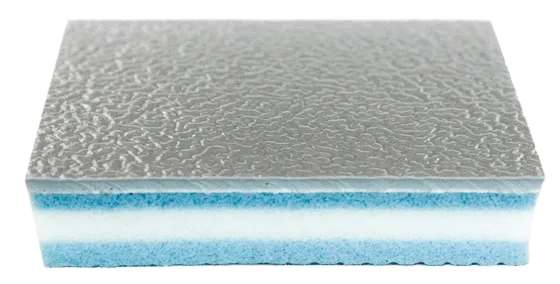

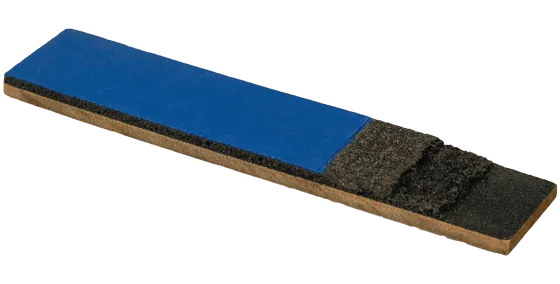

Modular Rubber is produced by mixing 100% recycled SBR granules and rubber fibers with a certain ratio of special polyurethane adhesive and pressing them in molds at appropriate temperature and pressure.

Thanks to its special surface texture, it minimizes slipping, providing significant comfort in walking areas and children's playgrounds.

- Produced in thicknesses ranging from 20 to 40 mm.

- Available in single or double-layer options.

- Can be manufactured as SBR or SBR + EPDM.

- Can be applied on concrete and sand surfaces.

- Prevents injuries and accidents due to its shock absorption.

- Has high abrasion resistance.

- Application is very practical.

- Ensures safe activity thanks to its non-slip feature.

- Suitable for use in hot and cold countries.

- Preferred for children's playgrounds and walking paths.

Projects

Frequently Asked Questions

1. What is modular rubber?

Modular rubber; These are rubber tiles produced in 40x40cm or 50x50cm dimensions, obtained by pressing a mixture of 1-3mm rubber grains and color pigments.

2. What are the stages of modular rubber production?

Modular rubber is produced by mixing 100% recycled SBR granules and rubber fibers with special polyurethane adhesive in a certain ratio and pressing them in molds at appropriate temperature and pressure.

3. What are the application areas of modular rubber?

Children's playgrounds, parks and walking paths.

4. What are the advantages of using modular rubber in walking path construction?

Thanks to the special texture on its surface, it minimizes slipping and provides significant comfort in walking areas and children's playgrounds.

5. What are the types of modular rubber flooring?

Modular rubbers are obtained by mixing pigment dyes from recycled materials.

6. What are the modular rubber floor color options?

Red, black and green are the standard colors, but other color options are also available.

Sports Flooring

Other Products